June 2011

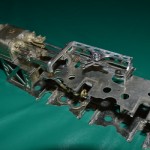

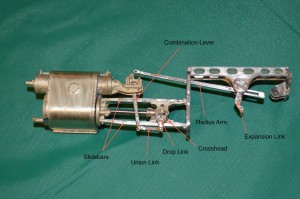

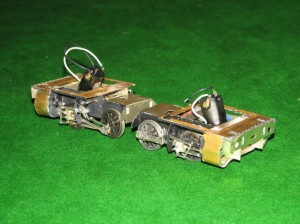

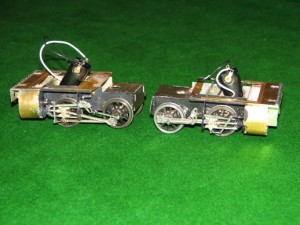

As you can see, both sets of driving wheels are now complete with coupling and connecting rods, plus valve gear.

If only I could put moving pictures on the website, I could proudly demonstrate how it all moves and proceeds along the track!

I have now fitted the bunker and the water tank onto the diving wheel assemblies of my model Garratt locomotive ….

I have now fitted the bunker and the water tank onto the diving wheel assemblies of my model Garratt locomotive ….

October 2011

My model of the industrial Garratt “William Francis” is coming along quite well, now.

My model of the industrial Garratt “William Francis” is coming along quite well, now.

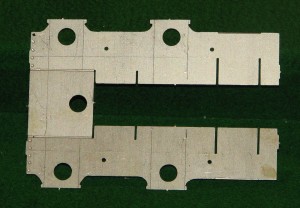

The first picture is of the two end units, with the rear one containing the coal bunker on the left and the front unit with a water tank on the right.

This is the central unit, with the boiler and cab.

This is the central unit, with the boiler and cab.

It’s a very complicated model, and the kit (originally bought by me over a decade ago), is far from perfect or comprehensive. It’s really just a starting point for building a model of this industrial locomotive – adding detail is very much needed. However that is the part which I enjoy most, so that is certainly OK by me.

November 2011

My Garratt. It’s an 0-4-0+0-4-0 locomotive. The prototype ran in an industrial complex centred around a large coal mine in Warwickshire. It’s taken me a year to get this far, being quite a complex project. Here you are, though. Just three minor details to go (nameplates and a clack valve on the right hand side of the boiler).

Then it will be on to the painting …

December 2011

So what have I been doing?

Well, the Garratt has progressed. The construction is now finished, and I’ve put the primer on it. It now looks a little like the prototype did when it emerged from the Beyer-Peacock work in Manchester and had its picture taken in “works grey”:

Well, the Garratt has progressed. The construction is now finished, and I’ve put the primer on it. It now looks a little like the prototype did when it emerged from the Beyer-Peacock work in Manchester and had its picture taken in “works grey”:

Also, I have decided that I should but no more model kits until I have built the one that I already have! A radical approach I know, and judging by the article that I read, many other people have multitudes of kits lying arond the house waiting to be started. The first benefit of this policy is that I have started to make the model of an LNWR gunpowder van. I’m not sure that the LNWR ever actually had such wagons. I have never been able to find a photograph of one like this kit is supposed to represent, and the instruction sheet which comes with the model is vague, inaccurate in parts, and covers several different models. The attraction of the model is that the LNWR is reputed to have painted these gunpowder vans vermillion, so I could legitimately have a bright red wagon on my railway! There is some doubt that this colour is true: the claim about the colour may be based upon a crude tinplate model made by Bassett-Lowke in the nineteen-fifties! Nevertheless I shall build one.

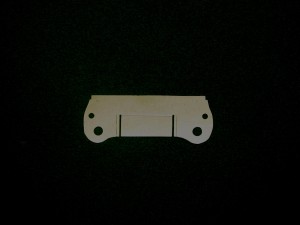

Here it is (as far as I have reached!):

For more entries, follow the links at the top or bottom of the pages, to go to “older posts”.