Yet another Midland Railway wagon! This time it is a D299, which is a bit like the D302 which I have already made (see prior entries), but this time it is a Slater’s kit. Like previous ones which I have written about, it is largely laser-cut wooden in construction, which I like.

“Etching” with a laser is also possible, and the parts fit pretty-well perfectly (computer design and computer-guided cutting also).

“Etching” with a laser is also possible, and the parts fit pretty-well perfectly (computer design and computer-guided cutting also).

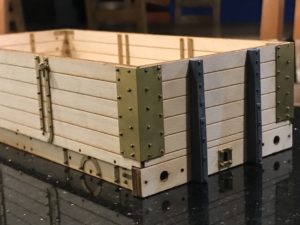

This is the body after all the wooden bits are stuck together.

There is a long and tedious part now fitting the “strapping” and braces, and all the tiny rivets through the strapping.

This is the result afterwards.

Next is the underframe.

But there is lots of lovely detail.

But there is lots of lovely detail.

The other part of the “Gauge 3 action” relates to my locomotive. The boiler has now been removed and the leaks found largely to relate to the boiler fittings (all the controls and gauges which come out of or go through the boiler).

A considerable relief – it pressure-tests well when all the fittings are removed and the holes for them plugged temporarily.

A considerable relief – it pressure-tests well when all the fittings are removed and the holes for them plugged temporarily.

Here (right) the front safety vale has been replaced with a (large) pressure gauge.

Once this was established, we could work on all the small parts – the regulator, the manifold fitting, the clack valves, etc (when we come to them I will explain what these arcane terms refer to).

Here is a picture with the “superheater tube” removed (the last tube before the steam reaches the cylinders, where it is superheated to get it well about the temperature at which water could condense in the cylinders).

Here is a picture with the “superheater tube” removed (the last tube before the steam reaches the cylinders, where it is superheated to get it well about the temperature at which water could condense in the cylinders).

Next is the regulator removal and remaking. Here is the old regulator. The regulator shaft has to go the entire length of the boiler.

Warwick Allison (who is doing much of this work with me helping as best I can) said that for a better long-term result we had better remake the regulator, to which I knowledgeably (ha, ha!) agreed. This involved me learning a little lathe-work, as well as learning much more about how steam engine actually works!

For instance, why does a steam-engine have a dome (usually)? Well it is to create a place to gather steam which is well-above the water level. If water is collected, you see, and gets into the cylinders then (not being compressible like steam is) it will severely damage the cylinders. Here is the loco. steam-collecting pipe after the dome is removed.

On a final note, Sue has said I can have a garden railway so that I can send a train out to her and her friends, sitting out in the garden, carrying a cargo of sparkling wine. So I had to check that my flat wagon would carry the load ….