I don’t often feel the need or have the inclination to indulge in political commentary, but have read a couple of articles in the Economist over the past week which I want to share some thoughts from.

I have been watching what I regard as the tragedy of “Brexit” from afar. It really affects me minimally, now, but for someone in my equivalent position in the UK it has nothing but “negatives” really. However I can see why it has happened, and in my opinion those who think that the result can somehow be reversed are living in an alternative reality, because the fundamental reason for the “Leave” vote has not changed, and will not change in the short run.

In my opinion, the vote to leave is democracy at its best, even if I disagree with the verdict.

For years, possibly decades, the “elite” (whoever they are, and I would probably be counted as one, were I still living in England) have prospered, but the lower socio-economic classes have not. In my opinion, the Thatcherite “trickle-down effect” has been demonstrated to be a false illusion. Perhaps the economically-literate always knew it was such. What has really occurred is that those in finance and the upper echelons of industry have become proportionately more wealthy, whilst those at the bottom of the social ladder have seen no benefits, or certainly have seen themselves relatively disadvantaged. The riches earned by the “Bosses” have never been shared with the “Workers”.

On top of that certain politicians have seen career advantage to denigrate the European Union at every opportunity (Boris Johnson is the prime example of this). So it can surely be seen as little surprise when the less-well-off in British society are firstly resentful of being told how well the country is doing (when their wages are stagnant even as the directors of companies take multi-million pound bonuses); and also see the EU as a source of many of their woes.

Brexit will, I believe, be disastrous for England (if Scotland achieves independence, then they may get some benefit from the process). However those hurt dis-proportionally will be the well-off and middle-classes. The poor of England may see little difference – if they were struggling before, and additional struggle from Brexit may go unnoticed. They may obtain some satisfaction from the relative discomfiture of the elite classes, at least.

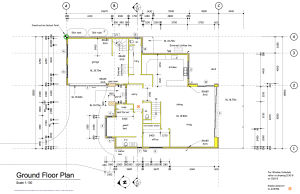

If you don’t think this can be true, click on this chart from the Economist and look at it.

It is from last weeks edition, and so reflects attitudes after all the negative publicity about Brexit that we have had recently.

My interpretation, in broad terms is this: the population still want all the advantages of EU membership, but without any of the obligations to countries poorer that the UK. If the referendum were re-held tomorrow, the result would be substantially unchanged. The EU is seen as responsible for the loss on manufacturing jobs and “blue collar” jobs in general, and even if finance-sector jobs have boomed, why should the population of Middlesborough/Liverpool/Glasgow care about that?

So unless Brexit can be shown to hurt the poor of England more than the rich, it is now inevitable.

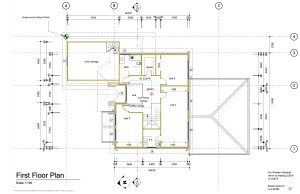

The other article in the Economist was about globalisation, which is under significant attack by Trump and others. the chart below is interesting for a number of reasons.

Globalisation is not going to stop, when large countries like India and Indonesia want it to happen. Also, protectionism (a la Trump) is not so easy in the era of the internet, Amazon, Alibaba, etc.

A final thought. Look at the percentage of a population who believe that their country is the best in the world. I knew that the USA would come top (a mass delusion that their society has much, indeed anything, to recommend it). However I always thought that France would come high on this scale (we don’t meet many French immigrants – but perhaps it would be different in SE Asia, for instance). However France is very lowly-rated. So who is the next country after the USA to believe that their country is the best? It is Australia. The difference, of course, is that we are right.