I have now put the steam pipes on and also added the back head and cab roof.

It is beginning to look the part ….

I have now put the steam pipes on and also added the back head and cab roof.

It is beginning to look the part ….

We are in Niseko (Japan) at present. I will only publish this after we return, however, given that it’s not a good idea to publish widely the fact that a family is away from home.

The skiing is fantastic, as usual. Actually it is a poor season for Niseko, but this means 1- 2 metres of snow instead of 10 – 12m, so that’s not too bad really. The two “boys” (183 and 193cm, of course) are having a really good time in the recently-fallen powder snow. It really is powder-like, because the cold of Niseko prevents it melting at all. Nick has hired special wider skis better to take advantage of the powder.

Long-gone are the days when Sue and I picked the boys up. These days it is they who pick us up, when they ski with us, which is less than half the time, these days. Actually it is I (David) who limits what we can do. I guess that I am lucky to be skiing at all, given that I injured my left leg again recently. Extensive micro-fractures at the top of my tibia/bottom of my femur. Fortunately it was just over six weeks ago, and even the orthopaedic surgeon accepted that I could ski (green runs and gentle blue runs were the instructions – in Niseko?).

We came here via Taiwan. As in previous years we broke the journey to or from Hokkaido somewhere which we had not seen before and were interested to visit – previous years were Seoul, Tokyo, Kyoto, Hong Kong. It helps of course to have an airline which flies both there from Sydney, and on to Sapporo.

Taiwan was very interesting. We only really saw Taipei,but that is a very interesting modern city, with a wonderful underground system and lots to see. The National Palace Museum is a standout attraction. It has much artwork and artefacts from the whole of China, brought there by the Nationalist forces during the civil war, as they retreated from mainland China.

Taiwan was very interesting. We only really saw Taipei,but that is a very interesting modern city, with a wonderful underground system and lots to see. The National Palace Museum is a standout attraction. It has much artwork and artefacts from the whole of China, brought there by the Nationalist forces during the civil war, as they retreated from mainland China.

The society is a modern example of Chinese culture, although Andrew had trouble reading the Chinese as it is written in “Traditional” script:so although Mandarin is spoken, the “Simplified Chinese” written language which he learned is not used. Chang Kai-Chek still casts a long shadow in Taiwan, despite his less-than-perfect human rights record. Outside the capital the countryside is beautiful, judged by our day trip to the North-East Coast.

Back to skiing, though: these holidays are a great time to spend with our “children” – we ski, play board games and card games, and go to really nice restaurants, of which Niseko has several. If you haven’t played Seven Wonders or Love Letter, try them, because they are really good: Love Letter especially – a game with only 16 playing cards which is utterly absorbing and entertaining. We mostly like to eat Japanese, but anything good will do! It’s not that expensive here in Australian terms – it’s easy to eat well for about A$25 / £10 per person.

Late December brings several important occasions.

First was Andrews 18th Birthday.

He had about forty friends around to celebrate this event, and all had a good time

This was the family at his party.

Then there was Christmas Day itself, with the family in the form of Sue’s parents.

A picture taken that night:

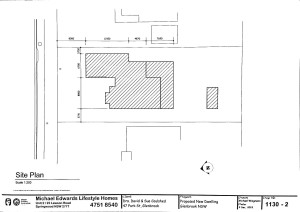

About five years ago we bought a block of land (OK, technically it has a house on it as well) in Glenbrook. This is a village on a train line with direct (just over an hour) trains into Sydney Central. The block is 200m from the railway station, and also 50M from shops, so it’s a good place to have a house.

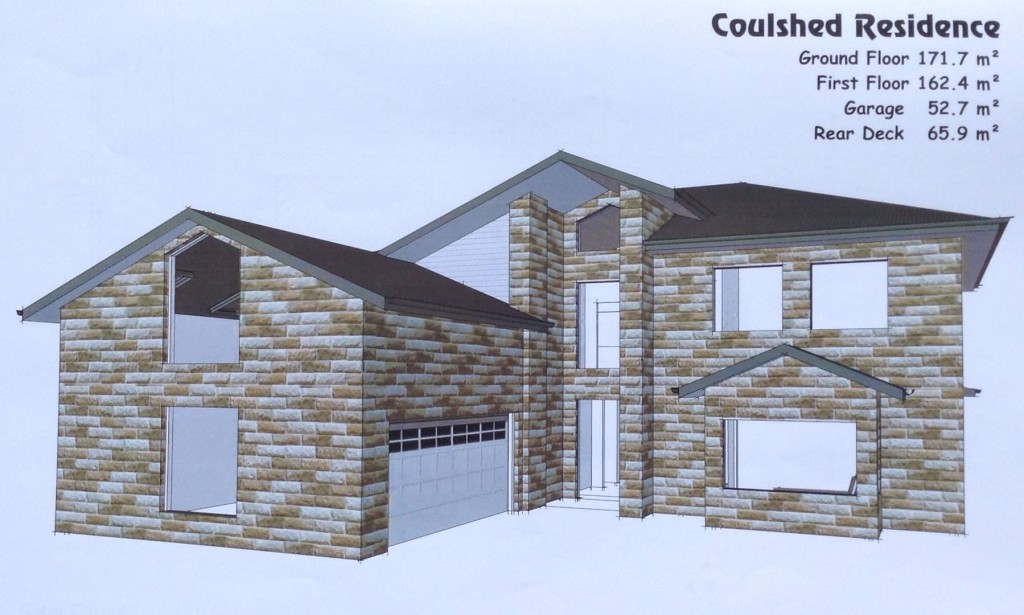

The exciting development is that we are in the first stages of building a house there. This is the initial design:

The block of land was attractive when we bought it because it is also flat – the survey shows only a variation in height of 1/2 metre throughout.

The block of land was attractive when we bought it because it is also flat – the survey shows only a variation in height of 1/2 metre throughout.

The block is about 50m by 20m, so there is plenty of room.

It will be as environmentally-friendly as we can make it. Double-glazed, sealed to make it thermally efficient, solar panels on the roof, rainwater-collecting into tanks, etc. The main construction will be in local sandstone, and we will try to use materials from as local a source as we can.

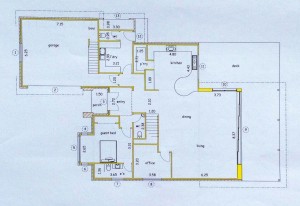

Click on the images to enlarge (if you are interested ….), these are the ground and first-floor plans:

Ground floor: large living area, garage swung around so as not to dominate the facade of the house, downstairs bedroom, large deck outside a large sliding glass door.

Ground floor: large living area, garage swung around so as not to dominate the facade of the house, downstairs bedroom, large deck outside a large sliding glass door.

Front entrance with view up to the second level.

Upper floor: three bedrooms. Large room above the garage for hobbies, etc.

Roof with “Velux” windows over the train hobby room.

Just a few pictures taken over the last few weeks.

Firstly, a kookaburra using our pool to have a bath!

Now it’s flying out.

Next, Sunday breakfast last weekend – summer has arrived. Avocado with lemon juice and black pepper, on toast.

Next, Sunday breakfast last weekend – summer has arrived. Avocado with lemon juice and black pepper, on toast.

All Brit.s idea of a typical scene in the Australian garden – this is a redback spider which I found under the lid of the pool-cleaning mechanism when I went to clean out the leaves there.

On the other hand, this could almost be an English scene, apart from the fact that this blackbird has made its nest in an orchid.

On the other hand, this could almost be an English scene, apart from the fact that this blackbird has made its nest in an orchid.

Blackbirds are introduced – feral – animals in Australia.

Today Sue and I (David) went to Bondi and met some friends of Sue’s ( a group of friends with whom she often goes gossiping walking around the foreshore of Sydney Harbour).  We went to look at the Sculptures by the Sea exhibition.

We went to look at the Sculptures by the Sea exhibition.

As an aside, we used our new Opal cards, which meant our trip from Blaxland to Bondi (two hours, by a train and two bus rides) return cost us a total $5 !

Sclutures by the Sea is very good. Sponsored by various firms, they select a number of artworks, some clearly designed specifically for the site, others less specifically inspired. The one below left was my favourite, but there were many good ones, a small selection I will put below.

It was a beautiful day. We arrived early, which was just as well. By the time we left (just after lunch) it was really crowded.

There was even a whale went past whilst we were there.

There was even a whale went past whilst we were there.

Cricket

Nick and I are playing cricket for Glenbrook-Blaxland Cricket club this year. I am in 8th Grade, Nick is in 5th Grade. I have been Mr Consistency this year. I’ve opened the innings both matches, facing the first ball, and in both matches I have lasted 13 overs and scored 5 runs, being out LBW each time!

Nick, however, has done somewhat better. Today he scored his first-ever century at cricket (he’s scored 52, 53 and 56 previously, but never over 60).

His team only scored 200 all out, so it can be seen that his contribution was important. Three sixes, and lots of one-bounce fours – this is Nick, after all.

This is what happens if you’ve scored 120 and are very, very tired ….

I’ve had an excellent weekend. It was a long weekend for reasons I cannot be sure of: someone said it was the queen’s birthday (which or what queen?), but I also heard it was a Labour (Labor?) Day weekend. It’s all the same to me ….

Anyway, one highlight was going on a mountain-bike ride with Nick.

Anyway, one highlight was going on a mountain-bike ride with Nick.

Both boys were at home, but only Nick came riding in the Glenbrook National Park with me. We went down the Ironbark trail, up Bennett’s Ridge to the Oaks picnic area on the Woodford Trail, then down the Single Track back to Glenbrook. A superb ride through the national park, early in the morning.

Even Nick was glad in  the end that I got him out of bed before 6-30 AM! It was hot later in the day, but cool as we pulled up the hill to the top of the Single Track.

the end that I got him out of bed before 6-30 AM! It was hot later in the day, but cool as we pulled up the hill to the top of the Single Track.

This is a picture of me just before haring down the Single Track.

The long downhill of the track must be one of the best rides in NSW/Australia/The World.

Hurtling down a track about a metre wide between trees and plants in the bush, at (I guess) 40-50 kph at times, trying to keep up with Nick (who starts off first, and after about 2km is 20 seconds ahead)! Exhilarating is only half of it ….

Later the same day I went to the AMRA exhibition in the Whitlam Centre in Liverpool. An excellent venue, about 40 minutes drive from MtRiv.

As I walked in, there was a live steam Garratt !!!!!

As I walked in, there was a live steam Garratt !!!!!

It is a model of the Darjeeling 0-4-0+0-4-0 Garratt. Radio-controlled, live steam, powered by “Metho” (or was it butane?), 0-gauge.

I want one ….

$8,000 in Australia, though.

There were other live steam loco.s that were more reasonably priced, however. “Only” $2k for this one, for instance:

There were other live steam loco.s that were more reasonably priced, however. “Only” $2k for this one, for instance:

Or about $4k for a Stanier 8F ….

Perhaps something for the garden railway in a our next house?

Brake gear.

A problem with all systems where power is picked up from the rails is that brake shoes realistically close to the wheel treads need to be isolated from those on the other side and from the frames, or else short circuits will occur. DC or DCC, I think. Now my system is going to have no pickups from the driving wheels, but the brakeshoes as made in the kit will short-circuit from one side to the other. What options do I have?

My first thought was to make new brake hangers by acrylic/epoxy molding. So I bought a Sylmasta kit and made molds for the brake hangers for the locomotive and tender.

I then made castings first in polyester (this was the plastic/resin provided in the molding kit):

I then made castings first in polyester (this was the plastic/resin provided in the molding kit):

These were too friable and brittle, however, so by default I tried molding in Araldite, which was more robust, but full of bubbles:

Even these looked unlikely to survive very long in general use, though. Contacting friends for advice suggested that I was trying to make castings of too much: it would be better to make castings of just the brake shoes.

However to do that meant filing all the brake shoes off the hangers (fourteen!) and both making and fitting accurate copies of the shoes onto each hanger. Then it occurred to me – I don’t need to take all the brake shoe off, just the surface which will be in contact with the wheel tread.

So I found some 2mm wide Plastikard strip, and have carefully filed sufficient off the surface of the brake shoes to glue a strip of Plastikard onto each shoe.

So the one on the left has been filed back, and the ones on the right show the Plastikard in place.

Once I came to try to fit them to the frames the next adjustment became necessary. As the frames are set at nearly the correct prototype width, they are much closer behind the wheels than in Finescale. If the brake hangers are fitted as made, the hangers are too far away from the frames, the shoes are outside the wheel rims and the outside parts of the shoes contact the coupling rods and stop them rotating. So now I became more grateful that the main parts of the brake hangers are metal, not epoxy! The two on the left of the picture above have had the posts from which the hangers are suspended shortened, whilst the right hand one is the original length. I think that this adjustment would have been near-impossible using plastic parts.

Now I just have to fit them, one or two at a time, and make sure the wheels still go round after each fitting.

Just an update. Partly because of the difficulty painting behind the driving wheels, and partly because I realised that I needed to put the balance weights on the wheels (and this would probably be much easier if I could lie them flat), I partly dismantled what I had done so far to put together the chassis. Also I realised that the return cranks were on at an exaggerated angle, and although this makes the valve gear move more satisfyingly, I should probably re-do the soldering to make it more realistic (10 degrees is right).

Of course to put the balance weights on is easier said than done. First of all I had to choose exactly which 8F I wanted to model! I found a picture of number (4)8067 which seems to have the right characteristics: a rivetted tender, balance wheels of the earlier type (not all of the weights are crescents) and based in the north of England. So number 8067 it will be.

Both types of weights are supplied in the MOK etches, as pairs (so four of each shape). Using the S7 Group Slaters wheels makes sandwiching the pairs of etches together relatively easy, one on each side of each wheel: the plastic spokes can be cut back a little to accommodate the etches. Not too much on the outer side, though, as the balance weights stand proud of the rims on the pictures I have seen.

I then filled in the gaps between the etches with Milliput filler.

I then filled in the gaps between the etches with Milliput filler.

Now seemed a good time to use Birchwood Casey metal black on the rods and valve gear, to obtain a good “polished steel” finish. I used Hi-Chem “All-Surface Primer” on the wheels (probably only available in Australia, but I’m sure motorcar paint shops anywhere would have a similar product) – it’s a marvellous very thin and very effective metal primer: it sticks to anything, in my experience even glass or granite benchtops! Therein lies a separate story, as you might imagine ….

Finally, a “dirty black’ initial topcoat. My engine is going to have a realistic (I hope) weathered appearance.

So there you are.

David