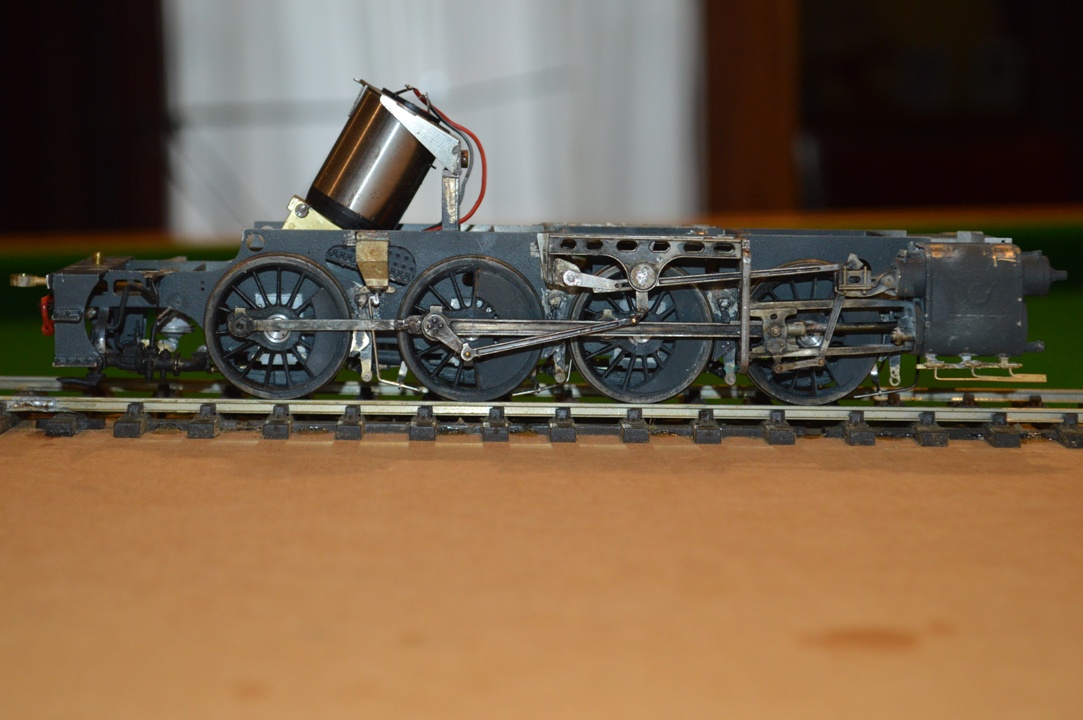

We are getting to the final stages of construction now.

The details is being added to the body and the frames. I have added much of the detail, provided by the kit manufacturer, to the body itself. This is about adding the sanding gear. On the prototype, this is the equipment aimed to spray sand in-between the rails and the driving wheels to improve adhesion in slippery conditions. There are three sandboxes, with tubes going out of them down to just in front of the leading driving wheel, and both in front of and behind the third driving wheel.

In this kit there are brass castings of all three sandboxes, even though two of them are inside the frames. The outside one goes to behind the third driving wheel and has an additional mechanism (I don”t know what function it has) beneath the sandbox itself. The sand-delivery tubes are represented by 0.8mm nickel-silver wire bent to shape, and I made support brackets from thin strips of scrap n/s with 0.8mm holes bored in the ends, twisted and bent to shape.

Here is the one for the outside sandbox, with a folded-up section of wire to represent the additional mechanism.

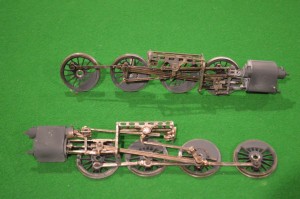

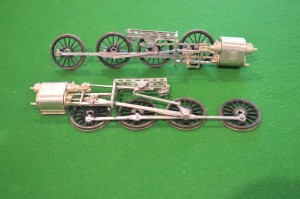

Once bent up and soldered onto the frames, this is the (unpainted) appearance.

The central sandbox, supplying sand to the front of the third driving wheel, was even more of a challenge, and in the end I made wire with multiple bends in it, allowing one end to be anchored to the sandbox, with the other supported by a bracket in position near the driving wheel.

The central sandbox, supplying sand to the front of the third driving wheel, was even more of a challenge, and in the end I made wire with multiple bends in it, allowing one end to be anchored to the sandbox, with the other supported by a bracket in position near the driving wheel.

This shows the course inside the frames of the central sandbox “tubing”.

This side-on view shows all the three sanding jets in place. Of the sandboxes, only the rear one is outside the frames and visible.