Category Archives: 2020 entries

Protected: England and Wales 2024

LSWR G6

I realise that as a narrative of building this model, my entries have not been good.

The model comes as a set of parts with mild steel frames and a mixture of brass and nickel silver sheets cut into parts, plus 3D-printed plastic (nylon?) detailed parts.

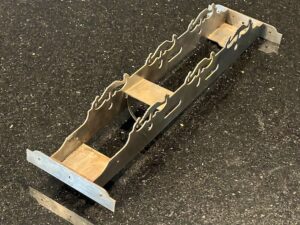

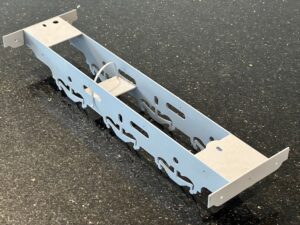

I started with the laser-cut steel frames, and used “silver-solder” to put them together, trying to make them exactly “square”. Silver-soldering steel is outside of my previous experience, but seemed to go reasonably well. Original post is in <Miscellaneous, incl. Rashmi’s wedding>. The main issue (discovered later) is that I didn’t adequately clean the steel of all the flux, which meant that I have had to face parts which were rusting! Trying to work out what to do about this led me to treating the frames with a combination of sand-paper, dipping in strong vinegar, and abrasion with various tools.

Once I had the frames back to bare metal, I had to start painting to lessen the risk of further corrosion. Here the frames are in primer:

You might notice that the guard irons (Used to clear track in front of the wheels) have been removed. I hadn’t realised that the two sets of guard irons had to be laminated before fixing them in place. So I took this opportunity to remove them and correct my mistake.

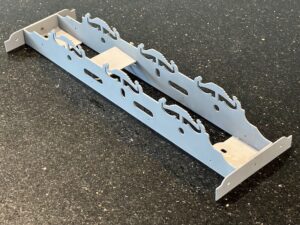

Frames painted black:

Meanwhile I had to decide what colour to paint the loco., because it is recommended in the instructions that the boiler and smokebox be painted early, because access for painting would be very difficult. I am generally an advocate of realistic appearances for models, and in the smaller scales I have done this. However for this larger model I decided to go for an “as-new” appearance – in fact there is a photograph of a G6 in LSWR passenger colours complete with lining. Even though the picture is black-and-white, i have decided to follow this historical record, although I my add a few soot and coal-dust stains, for realism.

So I started to work on the body/water tanks/boiler/smokebox unit. See <LSWR G6 Progress> ‘blog. To make up the body unit, it is necessary to construct the main structure from sheets of brass, laser-cut to exactly the correct dimensions. When it works, it’s very good, but when one misaligns something, the error can be magnified by the size of the part: see <LSWR Progress 3> to show how the boiler and smokebox don’t seem to line up once the boiler and water-tanks are put together as accurately as possible. Frustrating, but a little filler will probably disguise the defect(s).

Meanwhile I had to make a decision about how this engine would move. I decided to go for battery-powered radio-control. Another “first-time” for me. See See <LSWR G6 Progress 2>. I bought an “”off-the-shelf” solution with a 50:1 gearbox Slaters power unit, and so far it seems to work well (see the <LSWR G6 Progress 2> entry) – at first I bought the wrong battery-pack, and the motor is a 24V one instead of 12 volts, but this turns out to be unimportant.\ and with some adjustments, all is well.

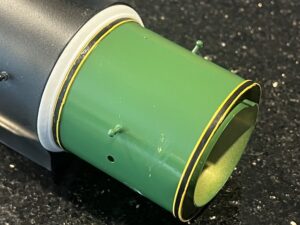

Now I am up to painting and lining the boiler. The correct shade of green is automotive RAL6002, I have been told, and I have both black paint and a small pot of automotive “Sunflower” colour for the lining. I have a German-origin HAFF bow-pen to do the lining (originally bought for my ScaleSeven Garratt model – search for “industrial garratt” on this website).

Looks pretty good on the whole, I think. The white plastic moldings with be painted black eventualy.

Here is the boiler section with the corrected lining colour(s):

These magnified pictures seem to show every flaw in my painting, but I think it will look OK when it is all put together.

LSWR progress 3

We have been away for a fortnight (in Uzbkistan – see the ‘blog) but I can now do some more on my G6. Actually it is not going as well as I had hoped.

The individual sub-assemblies seem to work OK and go together well; it’s just that the subssemblies seem not to align quite correctly. As you can see above, when the boiler/smkebox and watertanks are put together, then don’t quite align and there are cracks.

The individual sub-assemblies seem to work OK and go together well; it’s just that the subssemblies seem not to align quite correctly. As you can see above, when the boiler/smkebox and watertanks are put together, then don’t quite align and there are cracks.

On the other hand I can now put the handrails on.

Putting the handrails on proved quite a challenge: curving the part for the smokebox is difficult o get right.

I have reached the stage where it may be necessary to start painting as I go along. Once the subassemblies are united there will some little corners and areas under the boiler for instance, which will be quite difficult to get at by brush or airbrush.

I am hoping that one the various parts are united, and held together in various way, the alignment may all “come good”

A Hazard Reduction Burn

As you can see, I (David) have joined the Rural FIre Service. The RFS is a volunteer organisation, heavily subsidised by the state governments, and needs people like me to offer their time. Clearly some training is required to make it safe, and much equipment is needed for each “brigade”.

I went on my first assignment today – after months of training. As you can see from the picture, my first job as a firefighter was to light a fire ! Hazard Reduction burns are aimed to reduce the “fuel load” in the bush, by burning all the low undergrowth in a controlled manner, whilst allowing the trees to survive.

I went on my first assignment today – after months of training. As you can see from the picture, my first job as a firefighter was to light a fire ! Hazard Reduction burns are aimed to reduce the “fuel load” in the bush, by burning all the low undergrowth in a controlled manner, whilst allowing the trees to survive.

This was “small” HR burn – about 200m x 200m, and to do this takes lots of organisation – there were four brigades involved and ten or twelve “trucks” – four-wheel drive fire engines.

The HR burns can look just as dramatic as a bushfire.

We all have to have fire-resistant clothing, helmet, boots, etc.

We have to lay out all the hoses in advance, and it all has to meticulously planned – after all a burn which got out of control is not a good idea !

As much time is spent putting out the flame afterwards as was spent lighting the bush up initially with “drip torches” (I’m holding on in the top picture) which ar aimed to spread burning Diesel fuel/petrol mixture over the dry undergrowth.

As much time is spent putting out the flame afterwards as was spent lighting the bush up initially with “drip torches” (I’m holding on in the top picture) which ar aimed to spread burning Diesel fuel/petrol mixture over the dry undergrowth.

It was a very interesting day, but very tiring – hauling the hoses around is very tiring

It is seriously hot work as well – the radiant heat from flames even 5m away is too hot for your face without a mask or cloth covering.