I have to say that I feel a little foolish about this, but as a warning to others …. See if you could/would have made the same error.

The frames of my model 8F in Scale Seven I have decided to make at 29mm outside width (see previous posts). The nice etch of the main footplate made by Modern Outline Kits is for their Finescale construction, so the inside edges of the footplate would be too narrow for my model, and would hang over the insides of the frames.

It might not matter too much, but I thought this should be easily corrected, so I decided to re-form the line of rivets which runs parallel to the inside edge, then cut back the edge wherever it shows. I don’t have a rivet-forming tool which can precisely measure out and positon the rivets, but by careful measuring and scratching marks on the underside of the footplate, I seem to have managed a reasonable job. I also scratched on the footplate the width of the frames, ready to cut back the inside edges.

It might not matter too much, but I thought this should be easily corrected, so I decided to re-form the line of rivets which runs parallel to the inside edge, then cut back the edge wherever it shows. I don’t have a rivet-forming tool which can precisely measure out and positon the rivets, but by careful measuring and scratching marks on the underside of the footplate, I seem to have managed a reasonable job. I also scratched on the footplate the width of the frames, ready to cut back the inside edges.

So far so good. I thought.

Next I cut back the frame edges, carefully cutting (piercing saw) and filing straight edges.

Trial fit to frames: mistake exposed: what width should I have made the distance across the inside edges of the footplate?

NOT 29mm!

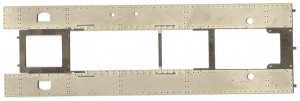

It should have been 29mm less twice the thickness of the frames – 27.5mm. So the footplate now ended just outside of the frames! This would look even worse than the overhang which I had decided to remove. What can I now do?

I found some 0.7mm nickel-silver wire which I had left over from a previous project, and carefully soldered it along the inside of the frames. Look carefully at the last picture (click to enlarge any of the pictures) and you might be able to spot the differences!

Oh, well!